Beddingo Sheets VS Standard sheets

I started working on Beddingo almost 5 years ago before it was actually called Beddingo. I read every piece of information I could find about bedding, and talked to tens of professionals, manufacturers, ran surveys with hundreds of customers, retailers, hotels, laundromats, and really did and still do whatever I can to enrich my knowledge about bedding. I've become quite an expert in bedding and I’d like to share some of the insights I learned, so let’s dive right in.

Beddingo Sheet has several advantages compared to standard sheets

No need to lift the mattress when changing sheets

One of the main difficulties in changing sheets is lifting the mattress.

A standard bedsheet is put on the bed by lifting the mattress and tucking the sheet’s edges under the mattress so that the heavy mattress will rest on the sheet’s edges and hold the sheet in place.

The problem is, that some people can’t lift the mattress, others just find it difficult, and it would be more comfortable for everyone if there was a way to not lift the mattress at all.

The problem also exists in hotels: housekeepers are among the top 10 professions with the most injuries and diseases, ranking even higher than mechanics (out of 800 professions and according to the US Bureau of labor statistics).

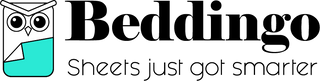

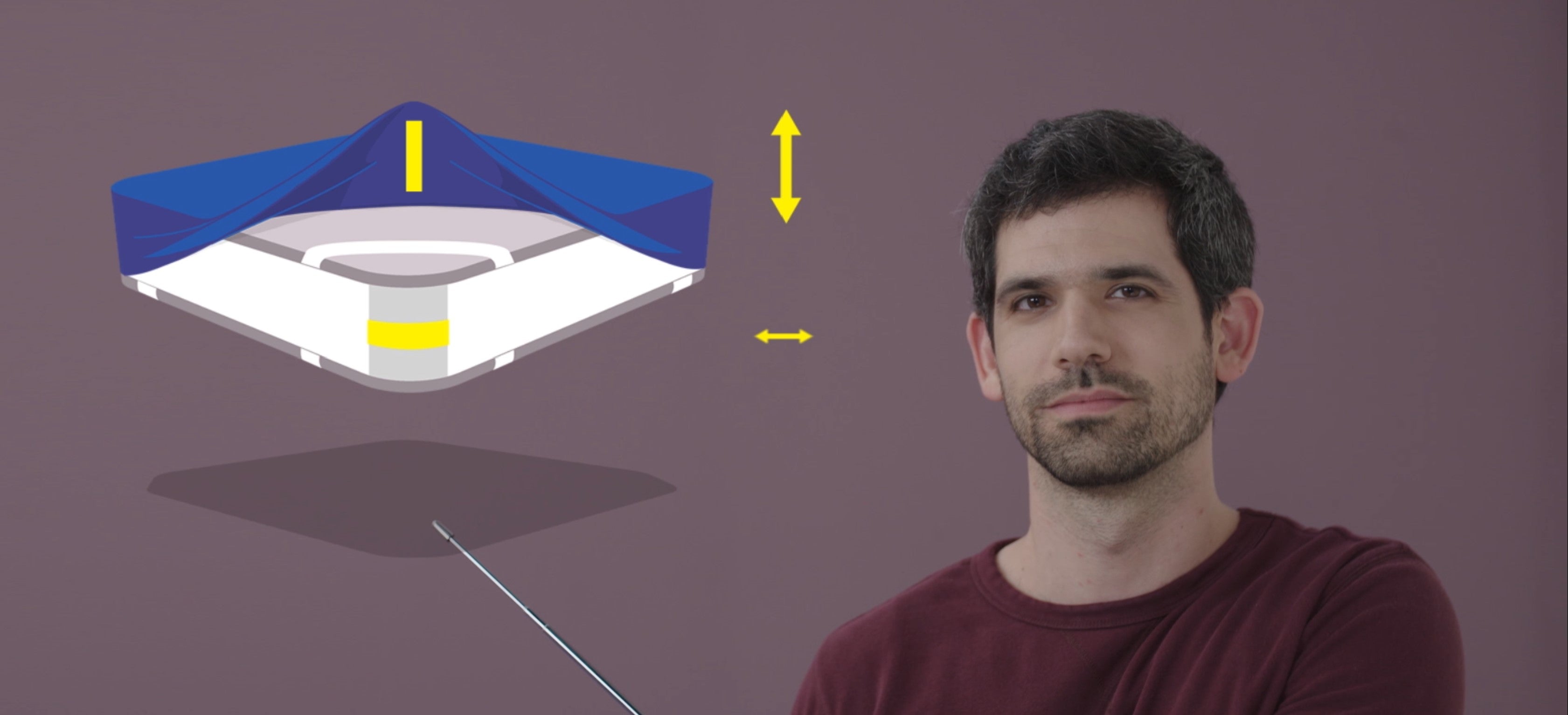

Beddingo Sheet is designed not to be tucked under the mattress, but rather to stay on the mattress by getting attached to the mattress corners, so there is no need to lift the mattress when putting on the sheet - It stays in place thanks to Velcro.

Because there is no need to lift the mattress and Beddingo Sheet’s corners stay in place, putting on the sheet also takes half the time and effort, as no lifting is required.

In addition to the Beddingo label and the washing instructions label in the corner of the sheet, there are 2 more labels: “LONG SIDE” and “SHORT SIDE” sewn to the middle of 2 sides, so you would able to put the sheet correctly on the first try.

A brief explanation about Velcro:

Velcro has two parts – the hook side (male) and the loop side (female). The male part is rough whereas the female part is soft. The female part is basically composed of a thin mesh of loops. Other than not being damaged or damaged when washed in a washing machine, it also curls up and therefore becomes better with time.

Velcro is very resistant to water, heat, etc. It is used in both firefighters and space suits.

Velcro lasts about 10,000 uses – in terms of the use in Bedding Sheets, it means dozens of years (more long-lasting than any fabric).

The loop side of the Velcro is sewn onto the sheet, and can be washed with any other items. The hook side is sewn on Beddingo Base, which doesn’t require washing. If desired, there is no need to wash it more than once a year (low-heat program and separate from other laundry, washing instructions can be found on the label sewn onto the base).

The hook side of Velcro stays clean and doesn’t catch dirt because it is fully covered by a bedsheet, and if you’re using mostly Beddingo Sheets, it also doesn’t pop off and the corners of the mattress are never exposed unintentionally.

Beddingo Sheet’s corners never pop off

The second main problem with fitted sheets is the corners - They pop off the mattress constantly.

Beddingo Sheets on the other hand are not. The Velcro strips on their corners, attach to the matching Velcro on Beddingo Base (which is dressed only once around the mattress), so they are well secured and never pop off.

You can even jump on the bed as long as you’d like - the sheet would stay connected to the mattress.

Surprisingly, they are really easy to disconnect if you’re just using a pilling motion.

The Velcro is vertically sewn onto Beddingo Sheet’s corners, along the seam of the corner, to strengthen the sheet’s corners and prevent the fabric from pulling. If the Velcro were not vertically sewn, the fabric would be pulled upwards from the Velcro, the corner would look untidy, and folds would be created in the fabric.

The Velcro on the base is sewn horizontally to allow wider room for maneuvering when placing Beddingo Sheet, for bed makers who just want to get it done and not waste time on placing the sheet’s corner at the exact spot. In fact, almost every placement of the sheet’s corner on the mattress corner will be locked and hold the sheet’s corner in place.

Additionally, the thickness of the Velcro strips on the sheet and the base is important - 1” and 1.6”, respectively. This thickness was chosen meticulously and after extensive trial-and-error, to allow for a corner that doesn’t slip on one hand and can be effortlessly released on the other.

Tidy appearance

Shape

Beddingo Sheet’s shape is different than a standard sheet. Beddingo Sheet has arcs along all 4 sides of the sheet. The arcs offset the fabric that is pulled toward the center of the sheet when placed on the mattress (under the weight of the person on top), creating a smooth appearance when observed from the side.

Elastic rubber

A standard sheet has rubber sewn alongside the sheet’s edges, supposedly allowing it to stay attached to the mattress at its bottom part. In Beddingo Sheet, the rubber is only sewn in the corners (12”, which is 30cm, to the right and left of each corner), that way there is a bit more stretch between every two adjacent corners so no air is caught between them and the sheet’s sides and the mattress, which would have caused a bloated, undesired appearance. Instead, the sheet appears tight and tidy.

Premium quality

Beddingo Sheets are made from 100% cotton - very long staples, Sateen weaved, and with 500 Thread Count.

Let’s break it down to understand better what makes it so premium.

100% cotton - as opposed to adding so synthetic material like polyester. Although fabric technology has advanced greatly and also polyester blended bedding could feel great, there is still a noticeable difference when compared to 100% cotton, but it really depends on more characteristics of the fabric.

Very long staples - ok, first of all, staples = fibers. The cotton plant looks like a puffball called the “boll” and contains many fibers - nearly 250,000 to be exact.

There are 3 different classifications of staple length - short - 1 1/8", long - 1 1/4", and extra-long - 2”, which is also familiar as Egyptian cotton. These length differences may seem small, but they make a big difference in the quality, strength, and softness of the cotton.

The longer the staple the more silky feel, delicate, soft, and the cotton.

Sateen weave - there are two main ways to make fabrics: knitting or weaving.

The fibers are first converted into yarn and subsequently, this yarn is converted into fabric.

Jersey sheets are knitted - that is (mostly) what makes them stretchy.

Woven fabrics are stronger and more structurally sound. Weaving includes the basic weaves, plain, twill, and sateen. Sateen uses a more exposed thread surface, giving the fabric a silky feel and luxurious sheen. It’s also more tightly woven and therefore typically heavier in weight than plain, making it ideal for year-round comfort.

500 Thread Count - you probably all heard that the higher the thread count - the better the fabric quality. It’s actually not always true because there are more factors to it, and also there is a threshold that above it, higher thread count doesn’t make the fabrics softer but actually sometimes the opposite.

We found out after a lot of testing, that 500 is the ideal number for us.

Our fabrics are the softest and with silky feel like no other fabrics, we ever encountered.

There is also something called the finishing process, which is the chemical process the fabric goes through before it cuts into bedding items, but more on that in a different post.

There are more characteristics we didn’t mention, but we tested them all before deciding to work with our current fabrics, and we’re pretty sure are fabrics are the best there are.

So there it is, all of that is why we at Beddingo believe our special Beddingo Sheet would be the new standard for sheets all around the world.

Do you still have questions about Beddingo Sheets? Contact us or email us at contact@beddingo.com.

Leave a comment